Our services

Product Development

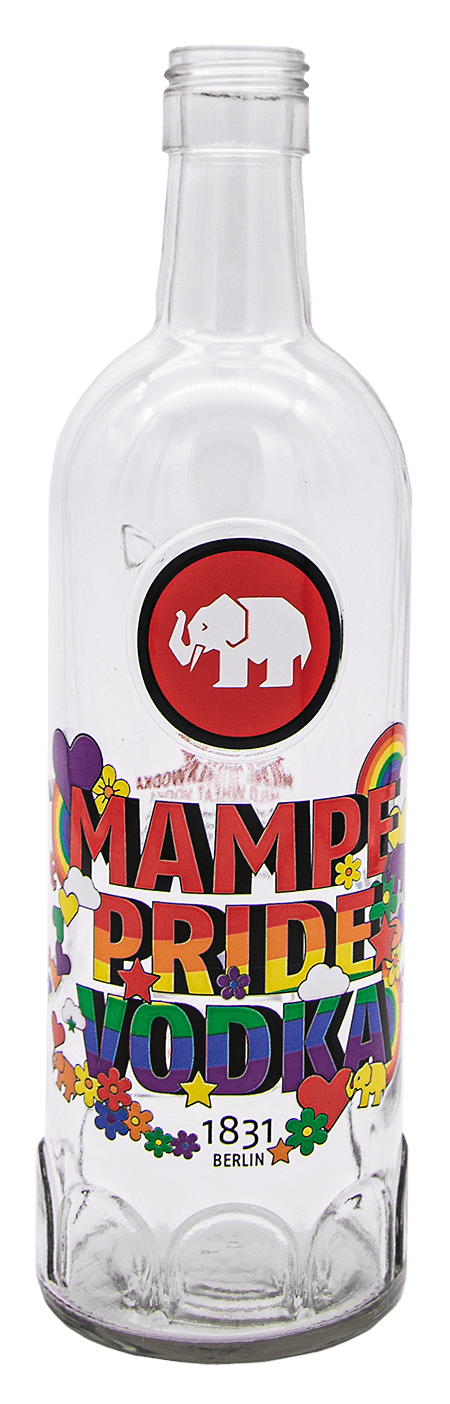

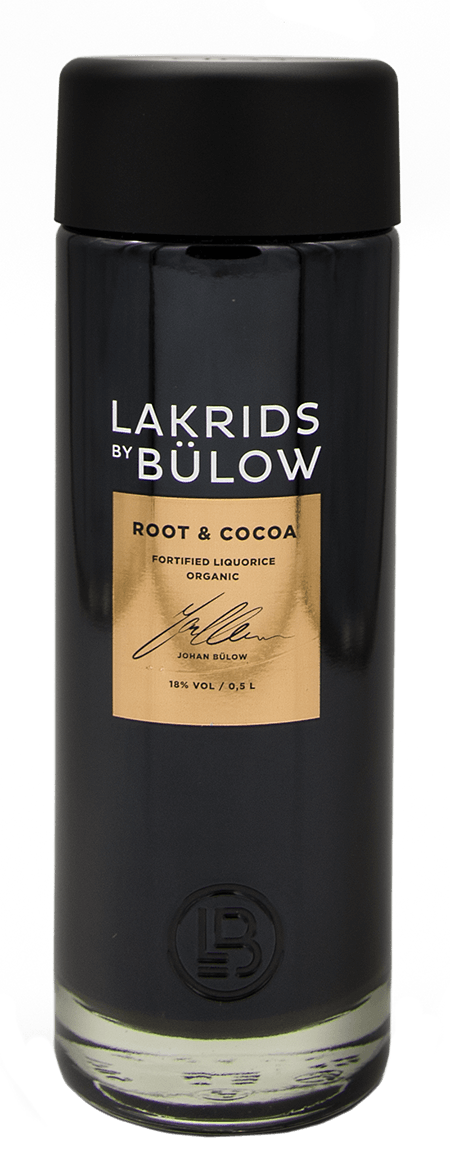

Together we will find the decoration that suits your product. Simply present your idea to us and our employees will work out a solution that meets your expectations.

At our locations we can offer you pre-press as well as screen production and colour mixing. This allows us to react flexibly and at short notice to your request. We create individual mock-ups, produce pilot series according to your specifications and arrange the print approval. Get an overview of our services or simply contact us directly if you have any questions.

Get an overview of our services or contact us us directly if you have any questions.